-40%

10pcs TIG Welding Tungsten Electrodes.040" 1/16" 3/32" 1/8" 5/32" by 7" Length

$ 4.64

- Description

- Size Guide

Description

10pcs TIG Welding Tungsten Electrodes.040" 1/16" 3/32" 1/8" 5/32" by 7" LengthItem Description

● 10-pk premium quality TIG welding Tungsten electrodes

● Color code: Red, Blue,Gray,Gold,Green,Purple

● AMERICAN Welding Society standard AWS A5.12M/A5.12:2009 conformance

● Available Size

.040"x7"(1.0x175mm) 10pk

1/16"x7"(1.6x175mm)10pk

3/32"x7"

(2.4x175mm)

10pk

1/8"x7"

(3.2x175mm)

10pk

5/32"x7"

(4.0x175mm)

10pk

.040"x7" 5pk & 1/16"x7" 5pk

1/16"x7" 5pk & 3/32"x7" 5pk

3/32"x7" 5pk & 1/8"x7" 5pk

●

You get one box of

Ten (10)

Tungsten electrodes at this price. FREE USPS or UPS Shipping within U.S.

WT20

(Red):

2% thoriated tungsten electrodes (AWS classification EWTh-2) contain a minimum of 97.30% tungsten and 1.70 to 2.20% thorium. They are the most commonly used electrodes today and are preferred for their longevity and ease of use. Thorium increases the electron emission qualities of the electrode, which improves arc starts and allows for a higher current carrying capacity. This electrode operates far below its melting temperature, which results in a considerably lower rate of consumption and eliminates arc wandering for greater stability. It also features a lower level of weld contamination than other electrodes. Unlike pure tungsten, these electrodes are only for specialty type AC welding (thin gauge aluminum or materials less than .060-in.), but they are exceptional for DC electrode negative or straight polarity on carbon and stainless steel, nickel and titanium applications. During manufacturing, thorium is evenly dispersed throughout the electrode. This evenness allows the electrode to maintain a sharpened edge—the ideal electrode shape for welding thin steel. Sharpening the electrode’s point, however, should be done with great care.

WC20

(Gray)

:

2% ceriated tungsten electrodes (AWS classification EWCe-2) contain a minimum of 97.30% tungsten and 1.80 to 2.20% cerium. These electrodes perform best in DC welding at low current settings but can be used proficiently in AC or DC processes. With its excellent arc starts at low amperages, ceriated tungsten has become popular in such applications as orbital tube and pipe manufacturing, thin sheet metal work or jobs where small and delicate parts are welded. Like thorium, it is best used to weld carbon and stainless steels, nickel alloys and titanium, making it an obvious replacement for 2% thoriated electrodes. Ceriated tungsten features slightly different electrical characteristics than thorium but most operators won’t be able to tell the difference. Using ceriated electrodes at higher amperages is not recommended. In these situations, the oxides will migrate quickly to the heat at the tip, removing the oxide content and nullifying its process benefits.

WL20

(Blue)

:

2.00% lanthanated tungsten electrodes (AWS classification EWLa-2.0) have excellent arc starting, low-burn-off rate, good arc stability and excellent re-ignition characteristics—many of the same advantages as ceriated electrodes. 2.0% lanthanated electrodes also closely resemble the conductivity characteristics of 2% thoriated tungsten, meaning, in some cases, it can replace 2% thoriated without having to make significant welding program changes. 1.5% lanthanated tungsten electrodes are ideal if you want to optimize your welding capabilities. Lanthanated electrodes work well on AC or DC electrode negative with a pointed end or they can be balled for use with AC sine wave power sources. The lanthana is dispersed evenly throughout the entire length of the electrode during manufacturing. It also maintains a sharpened point well, which is an advantage for welding steel and stainless steel on DC or the AC from squarewave power sources. Unlike thoriated tungsten, these electrodes are suitable for AC welding and, like ceriated electrodes, allow for the arc to be started and maintained at lower voltages. AC Compared to pure tungsten, the addition of 2.0% lanthana increases the maximum carrying capacity by approximately 50% for a given size electrode

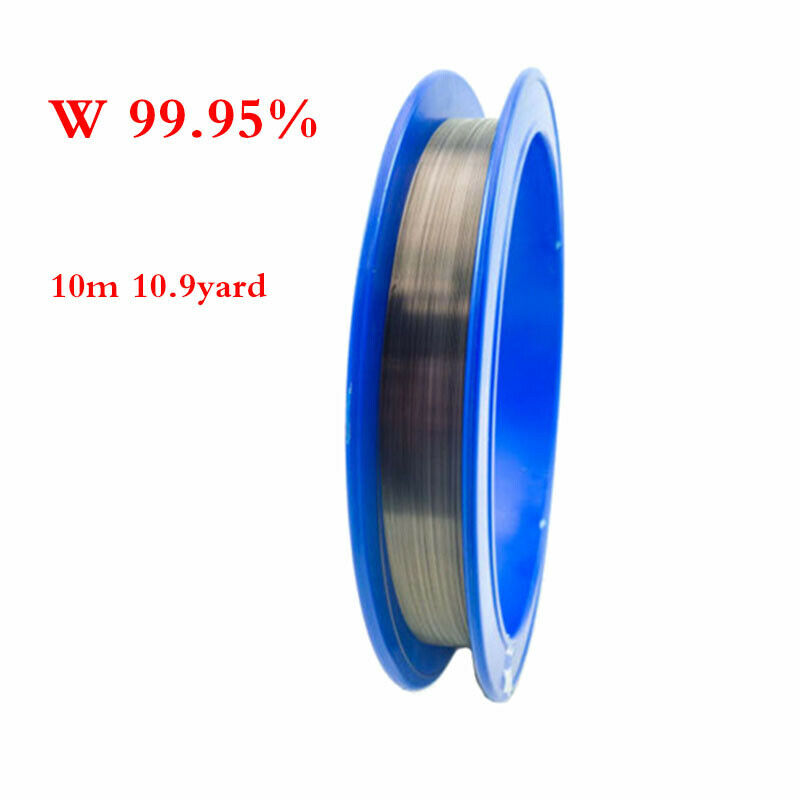

W

X

(NonRadioactive Comparable to E3 Purple):

Compound tungsten electrode is also known as three elements of rare earth. It is a non-radiation material. It is good to balance the electron mobility and evaporation rates, making tungsten electrodes to maximize their performances. For compound tungsten electrode, it’s easy to start and restart arc. If the welding cycle more than 15 minutes, its life will be last longer.

W

X

tungsten electrode tip burning significantly better than other tungsten electrodes. As three kinds of doping the oxide mixture in the electrode. It’s strict with the production process and the cost of production is more expensive.

WP

(Green)

:

Pure tungsten electrode is the earliest use of electrodes in TIG welding. It contains tungsten content minimum 99.5%, without other impurities.

Pure tungsten electrode is only as welding electrode under the condition of AC or resistance welding electrode. It can clean surface of base metal, welded ball become tapering when heating. This shape provides a good and balanced wave form for AC welding.

Pure tungsten electrode has a very high electron output, low vapor pressure, low resistance, good conductivity, thermal expansion, high elastic modulus bright. Therefore, stable arc at low currents, even as low below the 5A. It also does the welding aluminum, magnesium and other.

But the emission of electron demands high voltage and high no-load voltage of welding machine. The tungsten electrode is burned apparently if it works in the high current for a long time. The end may drop into molten pool after melting, which will bring the tungsten into the welding gap. So, it’s just used for welding some black metal or welding the unimportant parts.

WL15

(Gold)

:

1.5% lanthanated tungsten electrodes (AWS classification EWLa-1.5) have excellent arc starting, low-burn-off rate, good arc stability and excellent re-ignition characteristics—many of the same advantages as ceriated electrodes. 1.5% lanthanated electrodes also closely resemble the conductivity characteristics of 2% thoriated tungsten, meaning, in some cases, it can replace 2% thoriated without having to make significant welding program changes. 1.5% lanthanated tungsten electrodes are ideal if you want to optimize your welding capabilities. Lanthanated electrodes work well on AC or DC electrode negative with a pointed end or they can be balled for use with AC sine wave power sources. The lanthana is dispersed evenly throughout the entire length of the electrode during manufacturing. It also maintains a sharpened point well, which is an advantage for welding steel and stainless steel on DC or the AC from squarewave power sources. Unlike thoriated tungsten, these electrodes are suitable for AC welding and, like ceriated electrodes, allow for the arc to be started and maintained at lower voltages. AC Compared to pure tungsten, the addition of 1.5% lanthana increases the maximum carrying capacity by approximately 50% for a given size electrode.

SHIPPING POLICY

PAYMENT

RETURNS

FEEDBACK

SHIPPING POLICY

1. We accept PAYPAL payment only and ship to your eBay address.

2. Item will be shipped within 1 business day after received a verified payment. Different item is with different handling time

3. Free UPS or USPS shipping within U.S

4. Delivery Time upon purchase Locations

PAYMENT

1. PayPal payment accepted only.

2. Items will be shipped to your ebay address. Please make sure it is correct.

3. Payment must be received 4 days after auction

ended.

RETURNS

1. If product is defective or damage upon arrival, or wrong product shipped, please contact us immediately.

2.If you don't like them and they are in good condition,returns accepted within 30 days of delivery date. Return shipping will be paid by buyer

.

FEEDBACK

When you satisfied with our product and services please leave us positive feedback.

If a problem occurs, contact us immediately with any email request.

On Jul-17-20 at 01:21:07 PDT, seller added the following information: